cam and tappet experiment

One contained a soluble molybdenum friction modifier additive while the other did not. Universiti Tenaga Nasional 2006 Mechanical Design and CAD Laboratory CAM AND TAPPET EXPERIMENT OBJECTIVE The objective of the experiment is to investigate tappet motion for several different cam profiles and to study the effect of different followers.

What is a Cam.

. The objectives of the experiment is to investigate tappet motion for several different cam profiles and to study the effect of different followers For the first 180 degrees the theoretical value for displacement is 0. Day and Date experiment performed. A tappet having a rotary motion depresses a follower and a lever known respectively as the anti-friction bowl and the treadle arrangement by means of which the heald shaft is operated.

Data Observation and Results. The lubricating oil is the SAE 10W30 oil and supplied at 120C. APPARATUS - Basically the tribo.

Tgeom0 F0 U0 2 Equations 1 and 2 are written as func-tions of the cam angle 0 whereas camshaft torque is measured as a function of time t. Statement of Purpose Objective. DATA OBSERVATION AND RESULT DISCUSSIONFrom the data collected.

Cam lift mm 901 Max. Tappets are generally used for heald shedding. It will be pushed up along the guide.

Investigating the effects of coating on camtappet thermal elastohydrodynamic lubrication through numerical simulation has great significance in the design of coated camtappet conjunctions. When you move the book smoothly upward what happens to the pencil. It was proved by experiment using a full-scale engine rig that the tappets.

The objective of the experiment is to. The cam-tappet of an internal combustion IC engine is a rubbing pair with high load and severe lubrication condition. The cam and tappet are usually cylinders made of different metal materials.

The cam lobe and tappet contact area was lubricated by a jet of oil at 85 psi. A combined contact model for a cam-tappet with oil film stiffness is established. The jerk for this cam is therefore zero.

Tappet is a type of cam to which a rotary motion is given for the purpose of producing reciprocating motion in rods and levers by sliding contact. Tappet cam and wipers are names given indiscriminately to those irregular pieces of mechanism to which a rotary motion is given for the purpose of producing by sliding contact reciprocating motion in rods and levers. A simulation close to the application was presented by Chong for the camtappet contact of a valve train with a bottom-mounted camshaft according to the North American emission test cycle.

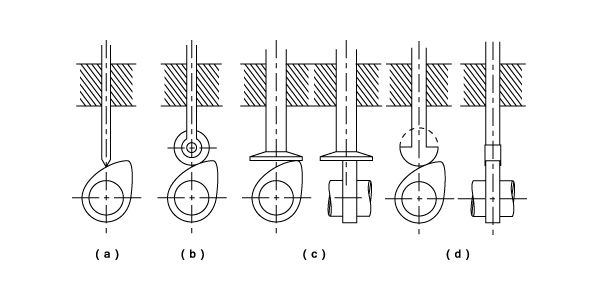

Study on driving mechanism and production calculation of tappet loom. Arctangentconcave asymmetric cam 3 roller tappet cup tappet and trailing lever 14 angled scale 0360 D100mm 5. The relation between 0 and t is 0 0tr ot 3 where 0tr is a trigger angle and co the angu-lar velocity of the camshaft.

When the rod is to receive a series of lifts with intervals of rest and thus forms. The results showed a good agreement in terms of the friction description in. At either 50 C or at 100 C.

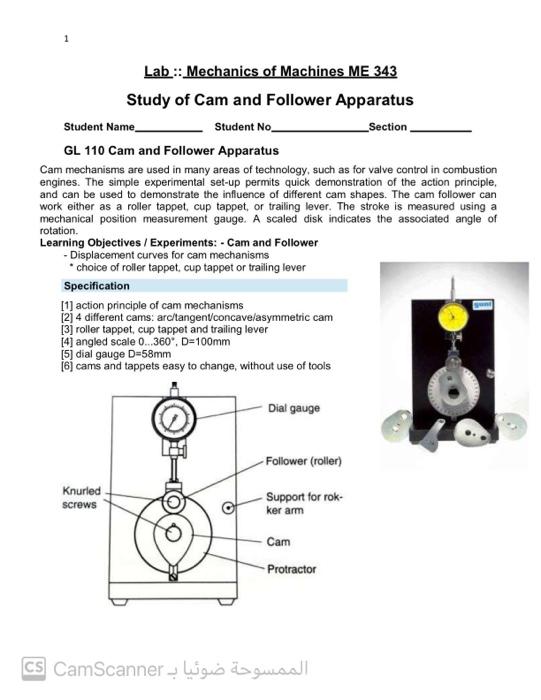

1 1 0564 2 2 2 1 1 1 2 1 2 W E E F z c P P UU U U V 14 In the Eq9 Fz is the normal force. The study applied the operating conditions of the thermo-elastohydrodynamically lubricated TEHL camtappet-contact of the valve train. - Cam and Follower - Displacement curves for cam mechanisms choice of roller tappet cup tappet or trailing lever Specification 1 action principle of cam mechanisms 21 4 different cams.

Study on tappet shedding mechanism. Oil film stiffness significantly influences the DTE of. The predicted stress of the pushrod is verified by a rig experiment.

Tappet cam and wipers are names given indiscriminately to those irregular pieces of mechanism to which a rotary motion is given for the purpose of producing by. Take a pencil and a book to do an experiment as shown above. 45 numerically investigated the e ects of mechanical and thermal coating properties on the TEHL camtappet-contact under full.

Tappetbore and camtappet friction torque and friction coefficient as a function of cam angle were derived from those measurements. Temperature and camshaft speed on e ciency improvement from a-CHZrC and a-CHX coatings on single automobile bucket tappets in contact with a cam. - Investigate tappet motion for several different cam profiles and to see the effect of different followers.

The tappet shim is made out of AISI 52100 steel and the cam lobe is induction. A tappet is a cam having some dwell period which controls the updown movement of heald shafts and the time of opening of the shed. The jerk for this cam is therefore in the form of a sine wave the same as the velocity plot.

Assuming that there is a line contact between the cam and tappet the Hertz formula for calculating the contact stress of the cam-tappet can be described by Eq98. Figure 6-1 Simple Cam experiment. The objectives of this experiment were to investigate the tappet motion for several cam profiles and to see the effect of different.

Geometry of a CamTappet System RESULTS The test engine in this study is an in-line 6-cylinder 2-valvecylinder OHV type diesel engine. Learning Objectives Experiments. Cam and tappet mechanism Graph Paper Tape and marker THEORY.

In this experiment the lubricant contains dispersed silica particles between 24 and 32 microns in size and given that the oil film thickness in a camshaft journal bearing is between 05 and 20 microns it is inevitable that a large proportion of the silica. When the rod is to receive a series of lifts with intervals of rest the piece is generally called tappet. EXPERIMENT 3 CAM Table of Content.

The contribution of the current study is to elucidate and compare the underlying friction reduction mechanisms of the aforementioned surface modifications in an application-orientated manner. In the case of engines we use cam and cam shaft above the intake and exhaust valve so that fuel and air. The two lubricants used were similar fully formulated oils.

611 A Simple Experiment. The surfaces of tappet inserts subjected to lubricated moving contact in a camtappet friction apparatus have been analyzed by IR reflectionabsorption X-ray photoelectron and Auger electron spectroscopies. The plot for the harmonic cam is in the form of a cosine wave.

Tappetbore friction and torque at the camshaft were measured for a direct acting bucket tappet using a camtappet friction apparatus. Data For Convex cam. This is the device mainly used in engines for converting rotatory motion into linear motion This can be explain using the simplest example in using engines.

Cam and tappet specifications Max. The cam and tappet specifications are shown h Table 2. THEORY Introduction Cams are widely used in engine machine tools textile and packaging.

Tappets are generally used for heald shedding. In order to raise the antiscuffing capacity of the cam-tappet a laser microprecision treatment was adopted to make the topography with artificial regular asperities on the working surface of tappets. Make the book an inclined plane and use the pencil as a slider use your hand as a guide.

Tm 1315 Cam And Follower Apparatus Infinit Technologies

Doc College Of Engineering Department Of Mechanical Engineering Memb331 Machine Design Cad Lab Universiti Tenaga Nasional Exp Title Experiment 3 Cam Table Of Content Thenna Suarez Academia Edu

Experiment 3 Group 2 Universiti Tenaga Nasional College Of Engineering Department Of Mechanical Studocu

Schematic Of A Cam Tappet Contact Configuration Download Scientific Diagram

Cam Tappet Contact Force Download Scientific Diagram

Cam Tappet Contact Force Download Scientific Diagram

Textile In Study On Nagative Tappet Shedding Mechanism

Flat Tappet Vs Roller Bs Pontiac Gto Forum

Cams Theory Of Machines Engineering Reference With Worked Examples

Solved 1 Lab Mechanics Of Machines Me 343 Study Of Cam Chegg Com